STRUCTURAL

BOLTING METHODS

DIRECT TENSION INDICATORS/DTIs

DTI's are individual bolt load cells, which measure pretension developed during tightening, regardless of torque resistance of the bolt. By far the simplest method is a DTI is put on one end of a bolt and tightened until the bumps are compressed enough so that a feeler gage cannot be inserted all around, or when the Squirter® DTI Squirt™ media appears at every available location. DTI's are completely independent of torque resistance of the bolt assembly, and because the compression of the DTI bumps can be visually observed, bolt installers tend NOT to leave the bolts with insufficiently compressed DTI's.

When using Squirter® DTIs, installers don't miss any bolts. Inspection by using a feeler gage (on a sample of the bolts only) can be done by anyone at any time. If the DTI is put on the nut end of the bolt, tightening can be done by one person because it is not necessary to hold the bolt roll.

Bolting Methodology, Standard DTI

- Snug the steel plies, in as many steps as necessary, to bring the steel into firm contact as required by AISC/RCSC section 8.1, without compressing the DTI below the Job Inspection Gap. If the DTI is compressed below the Job inspection Gap, during the snugging operation, remove and replace the DTI.

- After snugging, apply enough torque to compress the DTI until the residual gap is less than the Job Inspection Gap.

Bolting Methodology, Squirter® DTI

- Snug the steel plies, in as many steps as necessary, to bring the steel into firm contact as required by AISC/RCSC section 8.1, without compressing the DTI below the Job Inspection Gap. If the DTI is compressed below the Job inspection Gap, during the snugging operation, remove and replace the DTI.

- After snugging, apply enough torque to compress the DTI until the orange Squirt™ indication media is expelled from every available location and the residual gap is less than the Job Inspection Gap.

Inspection:

The inspector MUST:

- Verify Pre-Installation Verification has been performed.

- Verify the joint has been snug-tightened.

- Verify the DTI bumps have not been compressed beyond the job inspection gap during the snugging operation.

- Verify DTI bumps have been compressed below the job inspection gap after pretensioning.

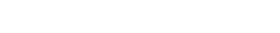

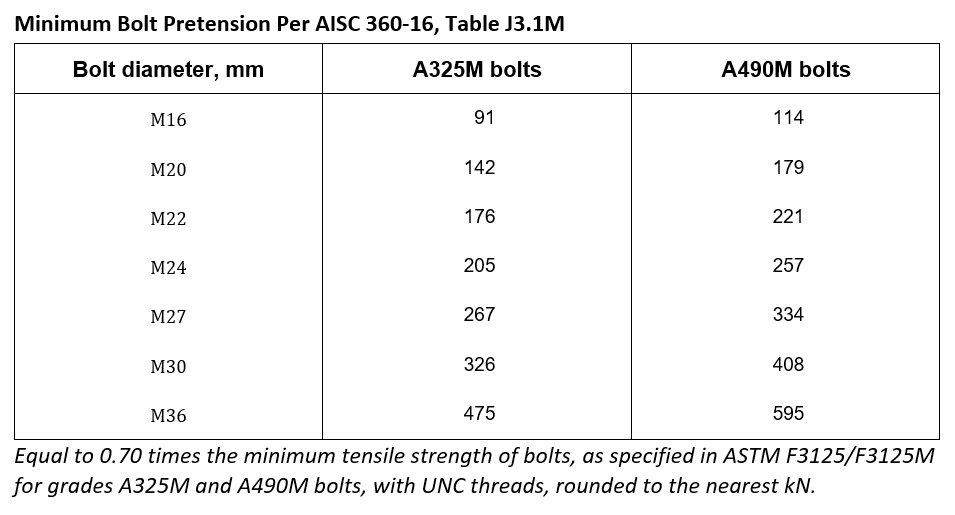

- Accept any fastener with a pretension greater than the minimum required6.

The inspector MUST NOT:

- Inspect DTI assemblies with a torque wrench.

- Compare the amount of turn between the nut and bolt with Turn-Of-Nut table 8.1.

- Reject DTIs that have been completely flattened during pretensioning.

6“A pretension that is greater than that specified in Table 5.2 or feeler gage refusal in all locations shall not be cause for rejection.”